Understanding the Chicken Cage Factory in Kenya: A 100,000 Unit Perspective

In the bustling poultry sector of Kenya, a chicken cage factory has become a cornerstone of efficient and scalable operations. This article delves into the intricacies of setting up a 100,000-unit chicken cage factory, offering insights for entrepreneurs and investors in the poultry industry.

Key Considerations for a 100,000 Unit Chicken Cage Factory

- Location and Infrastructure: The factory’s location should cater to easy transportation of raw materials and finished products. Access to a skilled labor force is crucial.

- Design and Manufacturing: The factory should utilize state-of-the-art equipment to ensure durability and efficiency of the chicken cages.

- Market Analysis: Understanding the demand and market trends in Kenya is essential to determine the production scale.

Statistics at a Glance

| Aspect | Details |

|---|---|

| Total Chicken Cages | 100,000 units |

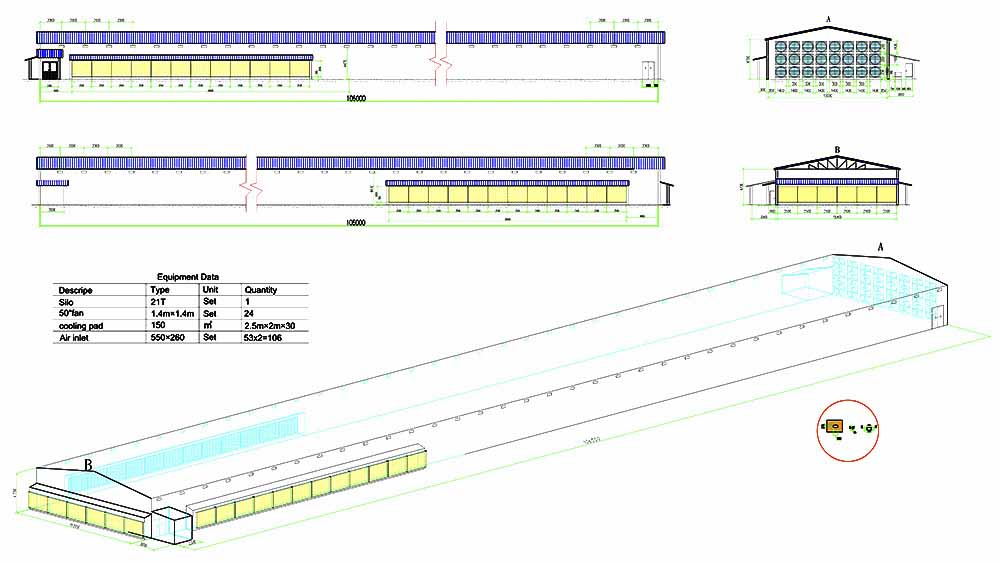

| Estimated Factory Size | 5,000 sq meters |

| Expected Employees | 150 workers |

Why Invest in a Chicken Cage Factory in Kenya?

Kenya’s poultry industry is witnessing robust growth. As of 2022, th e sector contributes around 10% to the country’s agriculture GDP. With the demand for chicken rising by 5-7% annually, the opportunity is immense.

e sector contributes around 10% to the country’s agriculture GDP. With the demand for chicken rising by 5-7% annually, the opportunity is immense.

Free Design and Equipment Quotation from LIVI Mechanical

At LIVI Mechanical, we understand the importance of a well-designed and efficient chicken cage factory. Conta ct us for a free design consultation and equipment quotation. Let our experts help you transform your poultry business into a thriving enterprise.

ct us for a free design consultation and equipment quotation. Let our experts help you transform your poultry business into a thriving enterprise.