What’s the Lifespan of an Automatic Feeding Line in Poultry Farming?

The efficiency and longevity of an automatic feeding line are critical factors for any poultry farming business. Understanding the expected lifespan of such equipment can help in planning maintenance schedules and budgeting for replacements. Below, we delve into the lifespan of an automatic feeding line, highlighting key factors that influence its durability.

What is the Average Lifespan of an Automatic Feeding Line?

On average, an automatic feeding line in the poultry industry can last between 8 to 15 years. However, this can vary widely depending on several factors, such as quality of construction, maintenance practices, and environmental conditions.

Factors Affecting the Lifespan of an Automatic Feeding Line

- Quality of Construction: High-quality materials and precise manufacturing techniques contribute significantly to the longevity of the feeding line. Sturdy components like gears, belts, and motors are less likely to fail quickly.

- Maintenance Practices: Regular maintenance is crucial to extending the lifespan of any piece of equipment. This includes cleaning, lubricating, and inspecting for wear and tear.

- Environmental Conditions: The operational environment can also impact the lifespan of the feeding line. Poultry farms in humid or dusty areas may require more frequent maintenance to prevent corrosion and wear.

- Usage Frequency: Continuous operation can lead to accelerated wear, while infrequent use may lead to equipment breakdown due to lack of proper lubrication or use.

Longevity Through Proper Maintenance

Implementing a proper maintenance schedule is essential. This could include:

- Daily checks for signs of wear and tear.

- Weekly lubrication of moving parts.

- Monthly cleaning and inspection.

- Annual comprehensive maintenance and service.

By adhering to a maintenance routine, you can significantly prolong the lifespan of your automatic feeding line.

Benefits of Longevity

Longer lifespan means reduced downtime, which is crucial in maintaining productivity in a poultry farm. Additionally, the cost savings from extending the life of the equipment can be substantial.

Table: Expected Lifespan and Maintenance Costs

| Component | Expected Lifespan | Estimated Maintenance Cost |

|---|---|---|

| Gearbox | 10-15 years | $200 – $400 |

| Belts | 5-10 years | $50 – $150 |

| Motors | 8-12 years | $150 – $300 |

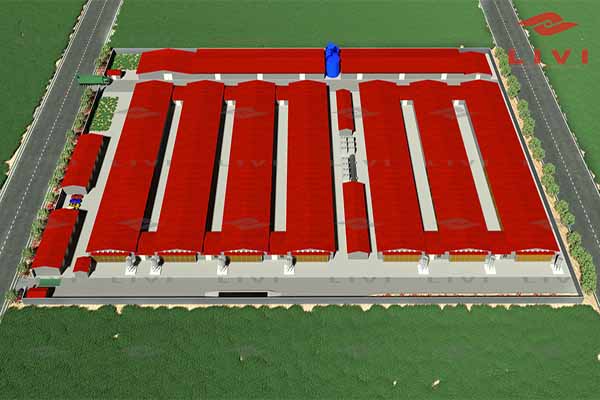

For expert advice on maintaining and maximizing the lifespan of your automatic feeding line, consider consulting with LIVI Mechanical. We specialize in providing innovative solutions for poultry farming.

the lifespan of your automatic feeding line, consider consulting with LIVI Mechanical. We specialize in providing innovative solutions for poultry farming.

Ready to take your farm to the next level? Leave a comment below with any questions or concerns you might have. We’ll be happy to provide you with a free chicken farming design plan and equipment quotation.