Automatic Manure Removal System for 400,000 Chickens in Togo: A Game-Changer for Poultry Farming

As the poultry industry continues to grow, efficient waste management systems are crucial for maintaining a clean and productive environment. In Togo, a country known for its chicken farming, an innovative automatic manure removal system has been developed to handle a staggering 400,000 chickens. This article explores the benefits of this system and its impact on the poultry industry.

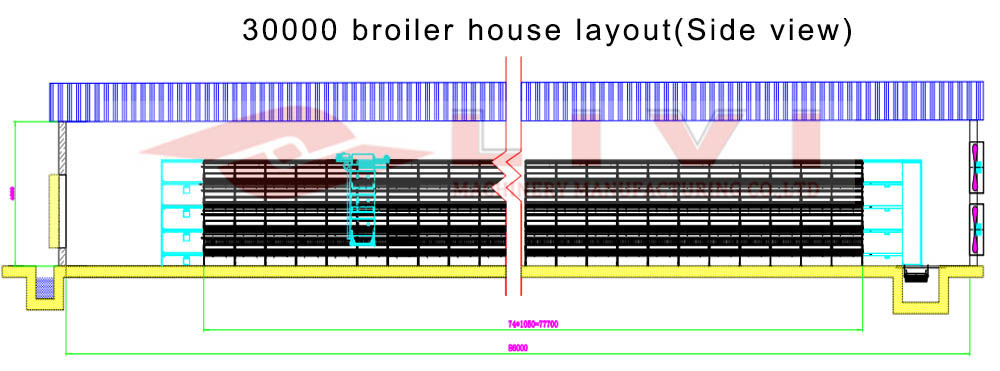

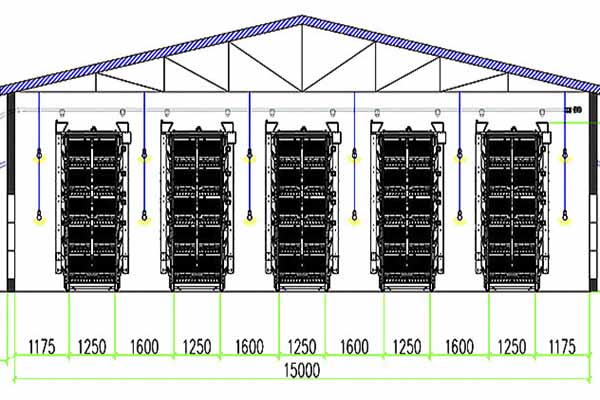

Understanding the System

The automatic manure removal system is designed to handle large-scale chicken farms, ensuring that waste is managed efficiently and hygienically. The system uses advanced technology to automate the process of collecting and removing manure, reducing the manual labor required and minimizing the risk of disease transmission.

- Automated collection: The system uses sensors to detect the presence of manure and automatically initiates the collection process.

- Hygienic removal: The manure is collected in a sealed container, preventing any odor or contamination.

- Easy maintenance: The system is designed for easy maintenance, ensuring that it operates smoothly for years to come.

Benefits of the System

Implementing an automatic manure removal system for a 400,000 chicken farm in Togo offers numerous benefits:

- Increased productivity: By automating the manure removal process, farmers can focus on other critical tasks, such as feeding and monitoring the chickens.

- Improved hygiene: The system ensures that the farm remains clean and hygienic, reducing the risk of disease outbreaks.

- Cost savings: By reducing the need for manual labor and minimizing waste, the system can lead to significant cost savings for farmers.

Case Study: Togo’s Largest Chicken Farm

The largest chicken farm in Togo has successfully i mplemented the automatic manure removal system. Since its installation, the farm has experienced the following improvements:

mplemented the automatic manure removal system. Since its installation, the farm has experienced the following improvements:

- Manure removal time reduced from 8 hours to just 2 hours per day.

- Manure collection efficiency increased by 30%.

- Overall farm productivity improved by 20%.

Conclusion

The automatic manure removal system for 400,000 chickens in Togo is a testament to the advancements in poultry farming technology. By implementing s uch a system, farmers can ensure a clean, productive, and cost-effective operation. If you are interested in learning more about this system or obtaining a free poultry farming design and equipment quote, please leave a comment below or contact us directly.

uch a system, farmers can ensure a clean, productive, and cost-effective operation. If you are interested in learning more about this system or obtaining a free poultry farming design and equipment quote, please leave a comment below or contact us directly.