Optimized Chicken Battery Cage System for 480,000 Chickens in Togo

As the poultry industry continues to grow, efficient and scalable farming systems are crucial for success. In Togo, a poultry farm is set to house 480,000 chickens, requiring a robust and reliable chicken battery cage system. This article outlines the key considerations for such a system, highlighting the benefits and features that make it ideal for large-scale chicken farming.

Understanding the Chicken Battery Cage System

The chicken battery cage system is designed to provide optimal living conditions for chickens while ensuring easy management and efficient use of space. This system consists of rows of elevated battery cages, where chickens are housed two or three per cage.

Key Features for a 480,000 Chicken System in Togo

- Capacity and Space Utilization: A system capable of accommodating 480,000 chickens must be carefully designed to maximize space utilization without compromising the well-being of the birds.

- Health and Comfort: The cages should provide adequate space for the chickens to move and access feed and water, reducing the risk of disease and ensuring their comfort.

- Automated Feeding and Watering: An automated feeding and watering system ensures consistent access to nutrients and hydration, contributing to healthier birds and higher productivity.

- Environmental Control: Efficient temperature and humidity control systems are essential for maintaining a healthy environment, particularly in large-scale operations.

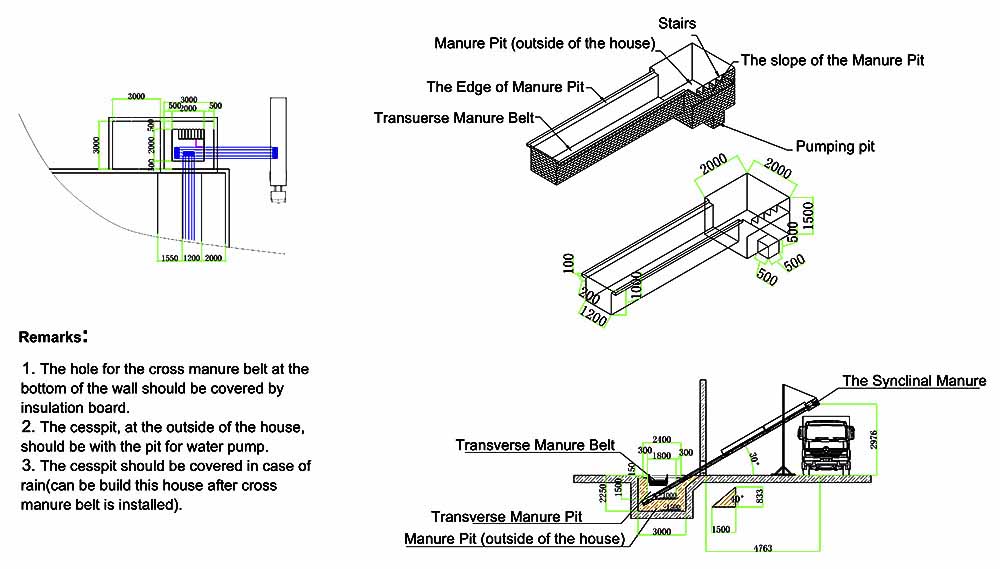

- Manure Management: An effective manure removal system is crucial for maintaining cleanliness and preventing disease.

Case Study: A Successful 480,000 Chicken Battery Cage System

In a recent project, a Togolese poultry farm implemented a customized chicken battery cage system designed to handle 480,000 chickens. The system featured the following components:

| Component | Details |

|---|---|

| Cage Design | High-quality steel with easy cleaning and maintenance features. |

| Automated Feeding | Continuous feeding system with sensors to adjust feed intake based on chicken weight and age. |

| Watering System | Automated drinker system ensuring constant water supply and minimizing waste. |

| Environmental Control | Advanced ventilation and climate control units to maintain optimal conditions. |

| Manure Removal | Continuous manure removal system with automated conveyors and storage facilities. |

As a result of this comprehensive system, the farm has experienced improved bird health, increased productivity, and reduced labor costs.

Conclusion

Implementing a chicken battery cage system for 480,000 chickens in Togo requires careful planning and consideration of key factors. By focusing on capacity, health, automation, environmental control, and manure management, poultry farms can create an efficient and profitable operation.

<img src="http://www.qualitychickenfarm.com/wp-content/uploads/2025/05/reliable- poultry-battery-cages-for-sustainable-farming-18.jpg” alt=”inserted image”>

poultry-battery-cages-for-sustainable-farming-18.jpg” alt=”inserted image”>

For more information on how to design and implement an optimal chicken battery cage system for your farm, please leave a comment below or contact us directly for a free, detailed design and equipment quote from LIVI Machinery.