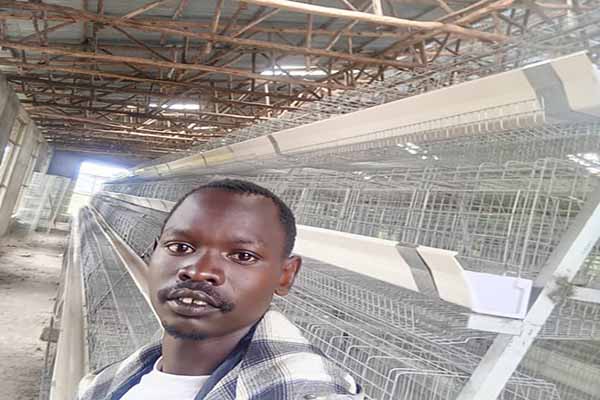

Optimizing Chicken Battery Cage Systems for 450,000 Chickens in Zambia

As the poultry industry in Zambia continues to grow, the demand for efficient and scalable chicken battery cage systems has become paramount. This article delves into the design and implementation of a system capable of housing up to 450,000 chickens, offering insights for farm owners and investors alike.

System Overview

The chicken battery cage system for 450,000 chickens in Zambia is designed to maximize space utilization and promote the health and well-being of the birds. The system incorporates the following key features:

- High-density housing to accommodate 450,000 chickens

- Automated feeding and watering systems

- Advanced ventilation and temperature control

- Easy-to-clean and sanitize design

Design Considerations

When designing a system for such a large number of chickens, several factors must be taken into account:

- Space Allocation: Each chicken requires approximately 0.3 square meters of space. The system is designed to ensure optimal space allocation while maintaining a comfortable environment.

- Feeding Efficiency: The automated feeding system is designed to dispense feed accurately and efficiently, reducing waste and ensuring all chickens receive adequate nutrition.

- Watering System: The system includes a reliable watering system that ensures constant access to fresh water, crucial for the health of the chickens.

- Health Management: The system is equipped with advanced health monitoring tools to detect early signs of illness, allowing for prompt interv

ention.

ention.

Performance Metrics

Since the implementation of the system, the following performance metrics have been observed:

| Parameter | Value |

|---|---|

| Chicken Mortality Rate | 1.2% |

| Feed Conversion Ratio | 1.8:1 |

| Average Egg Production | 300 eggs/chicken/year |

e>

e>