Automatic Poultry Equipment for 20,000 Chickens in Tanzania: The Ultimate Solution

Understanding the Needs of Large Scale Chicken Farming in Tanzania

In Tanzania, the poultry industry is experiencing significant growth, with many farmers aiming to expand their operations. For those looking to house 20,000 chickens, the need for efficient, automated equipment is paramount. This article explores the importance of automated poultry equipment and its benefits for a 20,000-chicken farm in Tanzania.

- Space Optimization: Automated poultry equipment ensures maximum use of space without compromising the health and well-being of the chickens.

- Health Management: Automated systems monitor environmental factors such as temperature, humidity, and CO2 levels, contributing to better flock health.

- Productivity: Automation can increase production and reduce labor costs, making the operation more profitable.

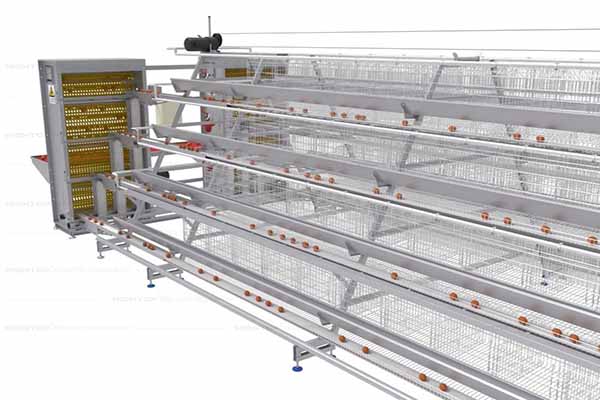

Key Components of Automatic Poultry Equipment for 20,000 Chickens

For a farm housing 20,000 chickens, the following components are essential for an automated poultry equipment system:

- Feeding Systems: Automated feeding systems provide precise nutrition to chickens, optimizing growth and health.

- Watering Systems: Continuous access to clean water is crucial. Automated watering systems ensure that the flock has access to water at all times.

- Airflow Management: Efficient ventilation systems maintain optimal environmental conditions for the chickens, reducing stress and disease risk.

- Environmental Monitoring: Automated sensors monitor temperature, humidity, and CO2 levels, ensuring a comfortable environment for the chickens.

- Health Monitoring: Automated systems can track individual chicken health and alert farmers to potential issues early on.

Case Study: Tanzania’s Largest Automated Chicken Farm

Tanzania’s largest automated chicken farm, with a capacity of 20,000 chickens, has seen remarkable results since implementing an automated poultry equipment system. The farm has experienced:

- Improved Flock Health: Disease rates have decreased significantly, thanks to the controlled environment provided by the automated system.

- Increased Productivity: The farm’s productivity has improved by 30%, resulting in higher profits.

- Reduced Labor Costs: Automation has decreased the need for manual labor, lowering overall costs.

Why Choose LIVI Mechanical for Your Automatic Poultry Equipment Needs

At LIVI Mechanical, we specialize in providing custom-designed poultry equipment solutions for farms of all sizes. Our expertise in automation and experience in the industry make us the perfect choice for your 20,000-chicken farm in Tanzania.

- Expertise: Our team of experts has years of experience in the poultry industry, ensuring that your equipment is tailored to your specific needs.

- Quality Products: We use high-quality materials and the latest technology to provide reliable, durable equipment.

- Free Design and Quotation: We offer a free design and equipment quotation for your farm, ensuring you get the best value for your investment.

Contact us today to get a free, customized design and equipment quotation for your 20,000-chicken farm in Tanzania. Let us help you transform your poultry operation into an automated success.