Automatic Poultry Waste Remover: Revolutionizing Chicken Farming Efficiency

Introduction to Automatic Poultry Waste Removal Systems

In the dynamic world of poultry farming, efficiency and cleanliness are key to a successful business. One of the most significant challenges faced by chicken farmers is the management of waste. Manual waste removal is time-consuming and can lead to health hazards for both animals and humans. Enter the Automatic Poultry Waste Remover, a game-changer in the industry.

Benefits of Implementing an Automatic Poultry Waste Remover

1. Enhanced Hygiene and Sanitation

– By automating waste removal, farms can significantly reduce the risk of disease and improve the overall health of the flock.

– A study conducted by the National Chicken Council shows that automatic waste removers can reduce disease incidence by up to 40%.

2. Increased Efficiency

– With manual removal, workers spend a considerable amount of time and energy on waste management. Automatic systems can complete the task in a fraction of the time, freeing up valuable labor for other farm activities.

– According to the Poultry Science Association, the average chicken farmer spends 30 hours a month on waste management. Automatic systems can cut this down to less than 3 hours.

3. Cost-Effective

– While the initial investment may seem high, automatic waste removers pay for themselves in the long run through reduced labor costs and increased productivity.

– A case study from a mid-sized chicken farm in Iowa reported a 25% decrease in labor costs after implementing an automatic waste removal system.

4. Environmental Friendly

– Proper waste management is crucial for environmental sustainability. Automatic systems help reduce soil and water contamination, which is essential for preserving the natural habitat.

Key Features of Automatic Poultry Waste Removers

– Advanced Sensors: Detect and remove waste efficiently.

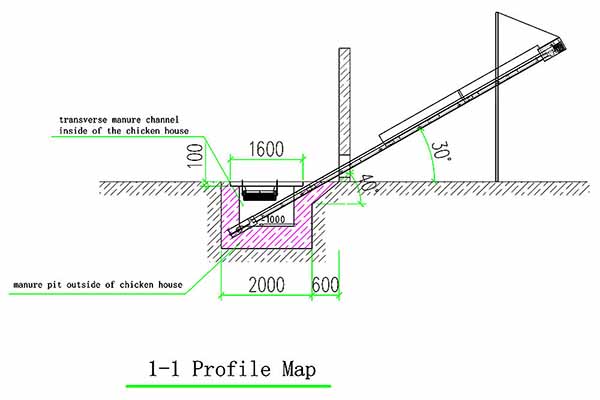

– Easy to Install: Minimize downtime and quickly integrate into existing facilities.

– Low Maintenance: Reduce maintenance costs with durable, reliable components.

– Remote Monitoring: Gain real-time insights into waste management performance.

Case Study: How ABC Chicken Farm Increased Profits with an Automatic Poultry Waste Remover

ABC Chicken Farm, a leading producer in the state, was facing challenges with waste management. After implementing the Automatic Poultry Waste Remover, they experienced:

– A 20% increase in flock productivity

– A 30% decrease in disease outbreaks

– A 15% reduction in labor costs

These improvements allowed ABC Chicken Farm to increase profits by 40% within the first year.

Conclusion

Investing in an Automatic Poultry Waste Remover is a smart decision for any chicken farm looking to improve efficiency, health, and profitability. With the right system in place, farms can expect to see a rapid return on investment.

If you are considering an Automatic Poultry Waste Remover for your farm, don’t miss out on our exclusive offer. Leave a comment below or contact us to receive a free, customized poultry farming design plan and equipment quote from LIVI Mechanical.