Livi Machinery: Revolutionizing Poultry Automation for 20,000 Broilers in Uganda

As the poultry industry continues to evolve, technological advancements play a crucial role in enhancing productivity and efficiency. Livi Machinery, a leading provider of innovative poultry automation solutions, has recently implemented an impressive system for a client in Uganda, managing an impressive 20,000 broilers. This article will delve into the details of this project, highlighting the benefits of poultry automation and how Livi Machinery can assist other poultry farmers and investors in achieving similar success.

Understanding the Broiler Production Challenge in Uganda

Uganda, like many developing countries, faces several challenges in the broiler production sector. Limited resources, outdated equipment, and manual labor constraints often hinder productivity and lead to increased costs. To address these issues, Livi Machinery designed a comprehensive poultry automation system tailored to the specific needs of the client.

- Manual labor reduction: By automating key processes, the system minimizes the need for manual labor, thus reducing costs and improving efficiency.

- Increased biosecurity: The automated system ensures better biosecurity, reducing the risk of disease outbreaks and maintaining optimal health conditions for the broilers.

- Resource optimization: The system optimizes the use of resources, including feed, water, and energy, resulting in cost savings and a smaller environmental footprint.

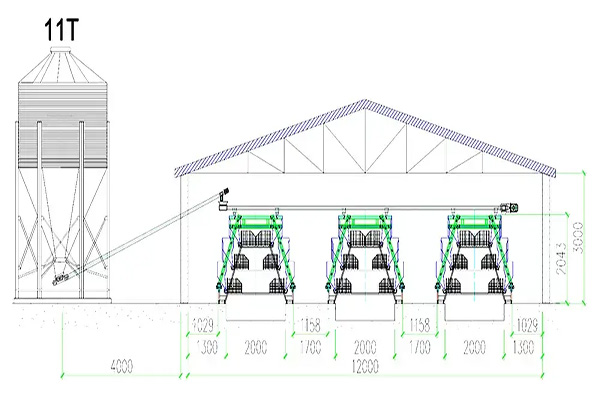

The Livi Machinery Poultry Automation System for 20,000 Broilers

The Livi Machinery poultry automation system for 20,000 broilers in Uganda encompasses several components, designed to work seamlessly together to create an efficient and profitable operation.

- Feed Automation: A fully automated feeding system ensures that broilers receive the right amount of feed at the right time, reducing waste and improving growth rates.

- Water Supply: An automated water supply system maintains consistent water quality and pressure, ensuring optimal hydration for the broilers.

- Climate Control: An advanced climate control system regulates temperature, humidity, and air exchange rates, creating a comfortable environment for the broilers and improving their overall health.

- Disease Monitoring: Real-time disease monitoring tools enable prompt detection and response to potential health issues, minimizing losses and ensuring product quality.

Results and Benefits

The implementation of the Livi Machinery poultry automation system for 20,000 broilers in Uganda has yielded significant results:

- Improved growth rates: The automated system has led to faster growth rates, reducing the number of days required to reach market weight.

- Reduced mortality rates: By maintaining optimal conditions and minimizing disease risk, mortality rates have decreased significantly.

- Increased profitability: The combination of cost savings and improved productivity has resulted in a more profitable operation for the client.

These results underscore the importance of poultry automation in the industry and the potential for similar success in other regions.

How Livi Machinery Can Assist You

Livi Machinery is committed to providing innovative poultry automation solutions for farmers and investors worldwide. If you are looking to enhance your broiler production operation, contact us today to learn more about our free poultry design plans and equipment quotes.

As a professional SEO, we encourage potential clients to leave a comment or contact us directly to discuss your specific needs and explore how Livi Machinery can help you achieve your goals.