Optimizing Chicken Battery Cages for 180,000 Chickens in Togo

In the dynamic world of poultry farming, ensuring efficient and humane conditions for large-scale operations is paramount. One such operation involves the housing of 180,000 chickens in battery cages in Togo. This article delves into the considerations and best practices for implementing such a setup, focusing on the unique challenges and opportunities involved.

Key Considerations for Chicken Battery Cages

1. Space Allocation: To accommodate 180,000 chickens, precise space allocation is essential. On average, each chicken requires 0.5 to 1 square foot of space. For a more comfortable environment, opt for 0.75 square feet per bird.

2. Cage Dimensions: A standard cage for chickens is usually 18 inches by 18 inches, which is suitable for one bird. Multiply this by the number of chickens to calculate the total cage requirement.

3. Ventilation: Ensure that each cage is well-ventilated to provide fresh air and reduce the risk of ammonia buildup, which can be harmful to the birds.

4. Egg Collection Mechanism: Implement an automated egg collection system to streamline the process and maintain hygiene.

5. Disease Prevention: Design the cages with an easy-to-clean structure to prevent the spread of diseases among the chickens.

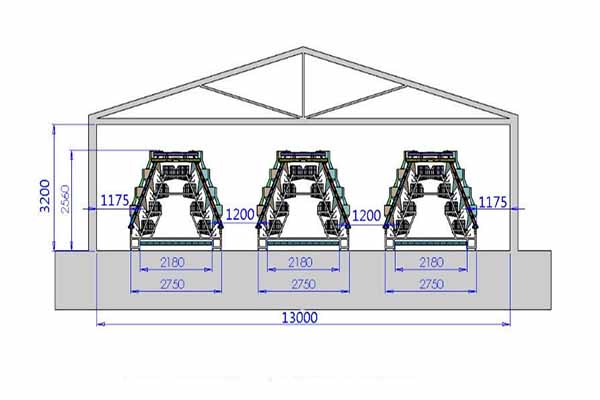

Technical Specifications

To house 180,000 chickens in battery cages, here are some technical specifications to consider:

– Total Cages: 180,000

– Total Space Required: Approximately 135,000 square feet

– Ventilation: At least 10 cubic feet of air per minute per chicken

– Feed and Water Systems: Automated to reduce waste and improve efficiency

Benefits of Automated Chicken Battery Cages

– Reduced Labor Costs: Automated systems minimize the need for manual intervention.

– Enhanced Production: Consistent conditions promote better growth and higher egg yields.

– Improved Animal Welfare: Humane design minimizes stress and injury to the chickens.

Conclusion

Implementing a battery cage system for 180,000 chickens in Togo requires careful planning and execution. By focusing on space allocation, ventilation, disease prevention, and utilizing automated systems, you can create an efficient and humane environment for your flock.

For more detailed information and to discuss a customized solution for your farm, we invite you to get in touch with us. As a leading provider of poultry farming equipment, Livi Mechanical can offer free design plans and equipment quotes tailored to your specific needs.