Optimizing Chicken Cages for 100,000 Chickens in Ghana’s Poultry Industry

Understanding the Market for Large-Scale Chicken Farming in Ghana

Ghana’s poultry industry has seen significant growth in recent years, with a growing demand for chicken meat and eggs. As one of the largest producers in West Africa, Ghana has the potential to support a chicken population of up to 100,000. To accommodate this scale, it is crucial for chicken farm owners and investors to consider efficient chicken cage systems.

Key Considerations for Chicken Cages in Large-Scale Farms

When it comes to housing 100,000 chickens, the choice of chicken cages is paramount. Here are some critical factors to consider:

– Space: Each chicken requires adequate space for movement and growth. A general guideline is 0.25 square meters per bird.

– Material: High-quality, durable materials like stainless steel or galvanized steel are recommended for long-term use and resistance to corrosion.

– Ventilation: Proper ventilation is essential to maintain air quality and reduce the risk of respiratory diseases. Ensure each cage has a ventilation system.

– Egg Collection: Easy-to-use egg collection systems can significantly improve efficiency and reduce manual labor.

– Health and Comfort: Cages should provide a comfortable environment for the chickens, with adjustable perches and nesting boxes.

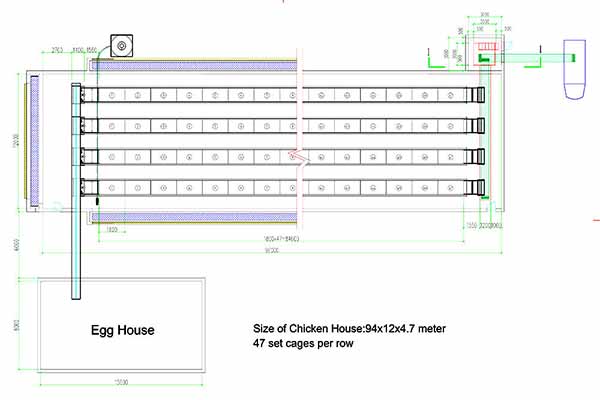

Case Study: Large-Scale Chicken Farm in Ghana

A successful example of a large-scale chicken farm in Ghana uses a system of 100,000 chicken cages. The farm has implemented the following:

– Automated Feeders: Reduces the need for manual feeding and ensures each chicken receives the correct amount of feed.

– Watering Systems: Automated watering systems maintain consistent water supply and reduce the risk of disease.

– Monitoring Systems: Real-time monitoring of the chickens’ health and behavior allows for quick responses to any issues.

Financial Considerations

Investing in a chicken cage system for 100,000 chickens can be costly. However, the long-term benefits, such as increased productivity and reduced labor costs, make it a worthwhile investment. Below is a breakdown of the costs associated with setting up a chicken cage system:

– Cages: $50,000 – $60,000

– Feeders and Waterers: $20,000 – $30,000

– Ventilation and Monitoring Systems: $15,000 – $25,000

– Labor: Reduced by approximately 50%

Conclusion

In conclusion, optimizing chicken cages for 100,000 chickens in Ghana’s poultry industry requires careful planning and investment. By considering the factors mentioned above, farm owners and investors can ensure a successful and profitable operation.

Stay Connected

Are you considering setting up a large-scale chicken farm in Ghana? Contact us today to receive a free, tailored chicken cage design and equipment quote from LIVI Machinery. Let our experts help you take your poultry business to the next level.