45000 Poultry Farming Layers Cage Price In Nigeria

In this case study, we explore a comprehensive project undertaken by Livi Machinery to design and supply an 45000 Poultry Farming Layers Cage Price In Nigeria. This initiative aims to demonstrate the efficiency and productivity benefits of automatic poultry farming.

Client Background

Our client, a progressive poultry farmer from Nigeria, sought to enhance his operations by adopting state-of-the-art automation technology. Motivated by the need for increased efficiency and production capacity, he partnered with Livi Machinery to achieve his goals.

Project Scope and Specifications

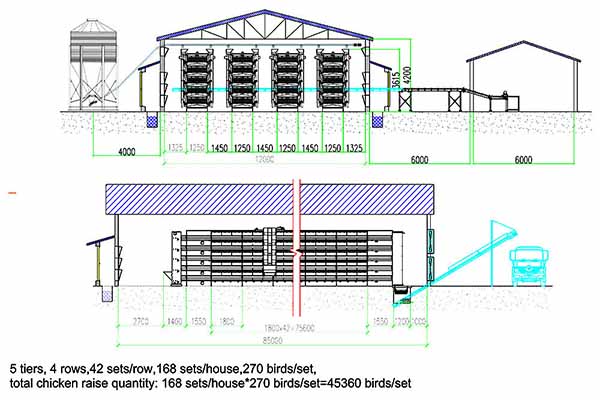

The project encompassed the design and layout of a modern poultry farm with the following specifications:

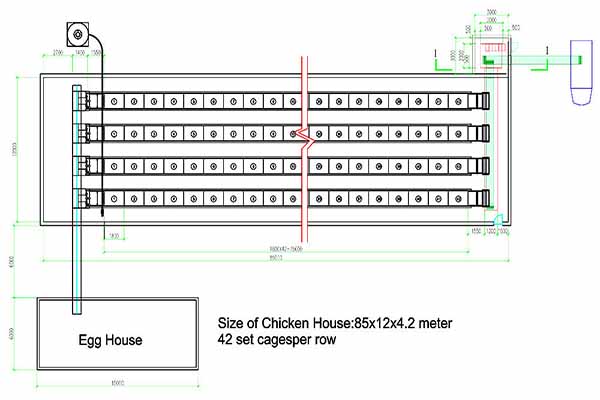

Chicken House Dimensions: 85 meters (length) x 12 meters (width) x 4.2 meters (height)

Egg Storage Room Dimensions: 15 meters (length) x 6 meters (width)

Capacity and Equipment:

Total Number of Hens: 45,360

Total Number of H-Type Layer Cages: 168 sets

Cage Specifications: 1800mm (length) x 1250mm (width) x 3610mm (height)

Cage Distribution: 4 rows with 42 sets of cages per row

Design and Layout

The modern chicken house was meticulously designed to optimize space and ensure efficient operation:

Cage Arrangement: Four rows of H-type layer cages, each row containing 42 sets of cages, providing ample space and easy access for automated systems.

Egg Storage Room: Strategically placed for convenient collection and storage of eggs.

Automated Equipment Provided

Livi Machinery supplied a comprehensive suite of automatic poultry equipment to ensure seamless farm operations:

H-Type Layer Cages:

Structure: 5-tier design

Capacity: 270 hens per cage

Automated Feeding System: Ensures consistent and precise feeding of all hens.

Egg Collection System: Efficiently gathers eggs, reducing manual labor and breakage.

Automated Manure Removal System: Keeps the environment clean and hygienic, improving hen health.

Environmental Control System: Maintains optimal temperature, humidity, and ventilation, enhancing hen welfare and productivity.

Implementation Process

The implementation process was executed in several phases to ensure a smooth transition to automation:

Initial Consultation and Planning: Detailed discussions to understand the client’s needs and customize the design.

Installation of Automatic Poultry Equipment: Professional setup of all automated systems and equipment.

Training and Support: Comprehensive training for farm staff to operate and maintain the new systems efficiently.

Benefits of Automatic Poultry Equipment

The introduction of automation brought significant benefits to the modern chicken house:

Increased Efficiency and Productivity: Streamlined operations and reduced labor requirements.

Improved Living Conditions for Hens: Enhanced hygiene and controlled environment.

Reduced Labor Costs: Automation minimized the need for manual labor.

Enhanced Egg Quality and Consistency: Automated systems ensured better handling and uniformity.

Environmental Impact and Sustainability: Efficient waste management and resource use.

Client Testimonial and Feedback

The client expressed high satisfaction with Livi Machinery’s solutions:

Experience: Positive feedback on the professionalism and expertise of the Livi Machinery team.

Performance: Notable improvements in farm productivity and efficiency.

Economic and Operational Impact: Significant cost savings and better overall farm management.

Conclusion

The project was a resounding success, showcasing the potential of automatic poultry farming layers cage price in Nigeria. Livi Machinery remains committed to advancing automatic poultry farming technology, helping farmers achieve higher efficiency, productivity, and sustainability.

If you need our product list and product quotation, please leave us a message.