Essential Chicken Equipment In Fully Automatic Chicken House

The poultry industry is experiencing a transformative shift towards fully automatic chicken houses, driven by the imperative to elevate production efficiency. Livi Machinery explains these Essential Chicken Equipment in fully automatic chicken house for chicken farmers. It encompass H-type stacked chicken cages, state-of-the-art egg collection systems, advanced manure cleaning equipment, precision feeding systems, and cutting-edge environmental control devices.

I. H-type Chicken Battery Cages

In the quest for efficiency, H-type chicken battery cages emerge as a game-changer. These Essential Chicken Equipment are meticulously designed to maximize space utilization within the chicken house. It offer not only an ergonomic environment for the poultry but also streamlining management and cleaning processes. The innovative design of H-type chicken battery cages contributes significantly to the creation of a productive and comfortable living space for chickens.

II. Egg Collection Systems

Efficiency takes center stage with advanced egg collection systems. These systems redefine the egg-gathering process by enhancing speed and minimizing losses. The integration of high-tech features ensures a seamless and automated operation, reducing the need for manual intervention. The result is a win-win situation for farmers and poultry, as these systems optimize productivity while ensuring the well-being of the chickens.

III. Manure Cleaning Equipment

Hygiene is paramount in fully automated chicken houses, and automated manure cleaning equipment plays a pivotal role in maintaining a pristine environment. By effortlessly managing waste, these systems contribute not only to the health of the poultry but also elevate overall sanitation levels, positively impacting the quality and safety of the final poultry products.

IV. Chicken Feeding Systems

Precision and efficiency define the modern poultry farm’s feeding systems. These advanced setups boast accurate measurements and controlled feeding processes, effectively minimizing waste and reducing operational costs. Their adaptability to the diverse nutritional needs of chickens at different growth stages ensures that poultry receives optimal nutrition, translating to improved health and productivity.

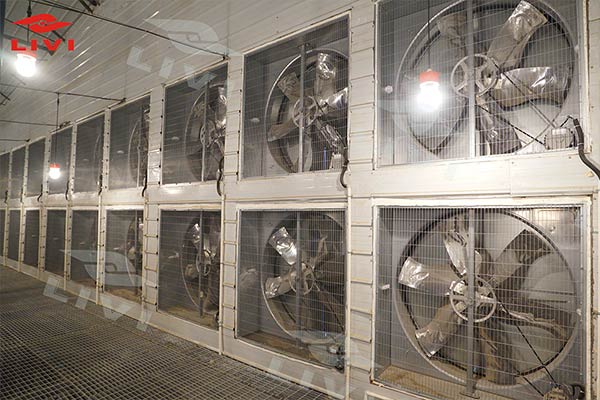

V. Environmental Control Devices

Creating the perfect environment for poultry is achieved through environmental control devices. These encompass systems regulating temperature, humidity, and ventilation. By fine-tuning these parameters, farmers can ensure a comfortable and healthy living space for their chickens, ultimately enhancing overall productivity and the quality of the end product.

Conclusion

The adoption of fully automatic chicken houses signifies a revolutionary step towards sustainable and efficient poultry farming. By incorporating these Essential Chicken Equipment of H-type chicken battery cages, advanced egg collection systems, automated manure cleaning equipment, precision feeding systems, and environmental control devices, farmers can revolutionize their operations. We express our sincere appreciation to those considering these modern practices and eagerly anticipate the prospect of collaborative success in the future of poultry farming.

Contact Information and Inquiry:

For those eager to embark on the journey of fully automated poultry farming, Livi Machinery stands as a leading provider of cutting-edge solutions. Chicken Farmers are encouraged to reach out for a free chicken farm design proposal and a complimentary quote.

Contact us today at WhatsApp: +86 17344898347 or via email at [email protected] .

In addition, you can leave us a message to inform us of your breeding quantity and chicken house size. We will contact you within 24 hours.