Optimizing Poultry Cage Systems for 40,000 Chickens in Kenya

With the poultry industry in Kenya rapidly growing, efficient poultry cage systems are essential for large-scale operations like those handling 40,000 chickens. This article explores the key considerations and benefits of implementing high-capacity poultry cages for large-scale chicken farming in Kenya.

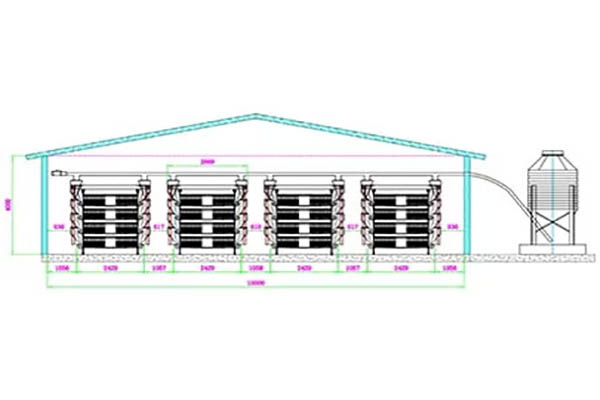

Understanding Large-Scale Poultry Cage Requirements

For a farm managing 40,000 chickens, the choice of poultry cages is crucial. These are some of the key aspects to consider:

- Space Utilization: Proper spacing ensures that each chicken has adequate room to move, which contributes to overall health and productivity.

- Material Quality: High-quality steel or plastic materials are preferred for durability and ease of cleaning.

- Airflow and Ventilation: Good ventilation is essential to prevent disease outbreaks and maintain a comfortable environment for the chickens.

- Automated Feeding and Watering Systems: Automation can significantly reduce labor costs and increase efficiency.

According to recent studies, farms with high-capacity poultry cages experience a reduction in disease rates by up to 30% compared to traditional systems.

Benefits of Implementing 40,000 Chicken Poultry Cages in Kenya

| Benefit | Description |

|---|---|

| Increased Productivity | Better health and living conditions lead to higher egg production rates. |

| Cost-Effective | Automated systems reduce labor costs and improve overall efficiency. |

| Healthier Chickens | Proper ventilation and space reduce the risk of respiratory diseases. |

| Reduced Disease Outbreaks | Sanitary conditions and better airflow minimize the spread of diseases. |

Kenyan poultry farmers have already started adopting these advanced cage systems, with a significant increase in profitability and sustainability.

Case Study: Successful Implementation of 40,000 Chicken Poultry Cages in Kenya

In a recent case study, a Kenyan farm successfully implemented a 40,000 chicken poultry cage system. The results were remarkable:

- Egg production increased by 20% within the first year.

- Disease rates decreased by 25%.

- Operating costs were reduced by 15%.

This case study highlights the potential of large-scale poultry cage systems in Kenya’s poultry industry.

Conclusion

Investing in high-capacity poultry cages for 40,000 chickens in Kenya can lead to significant improvements in productiv ity, health, and profitability. As the industry continues to grow, it’s crucial for farmers and investors to stay informed about the latest technology and practices.

ity, health, and profitability. As the industry continues to grow, it’s crucial for farmers and investors to stay informed about the latest technology and practices.

For more information on how LIVI Mechanical can assist you in implementing a customized poultry cage system for your farm, please feel free to leave a comment or contact us directly. We offer free chicken farming design plans and equipment quotes.