Chicken Farm Solution Of 200000 Layers In H Type Battery Cages

In the endeavor to efficiently accommodate 200,000 layers within H type Battery Cages, meticulous planning and strategic design are paramount.

In the endeavor to efficiently accommodate 200,000 layers within H type Battery Cages, meticulous planning and strategic design are paramount. Below outlines the comprehensive solution for such a venture:

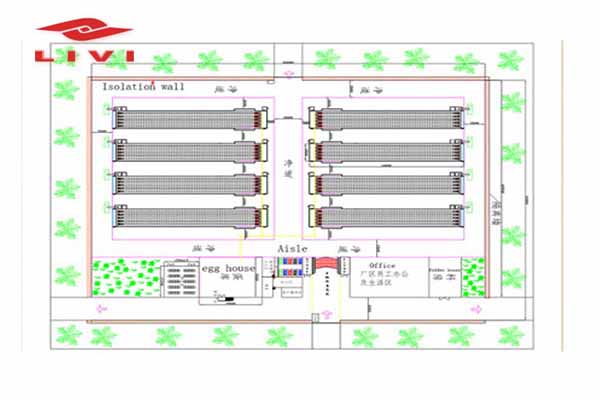

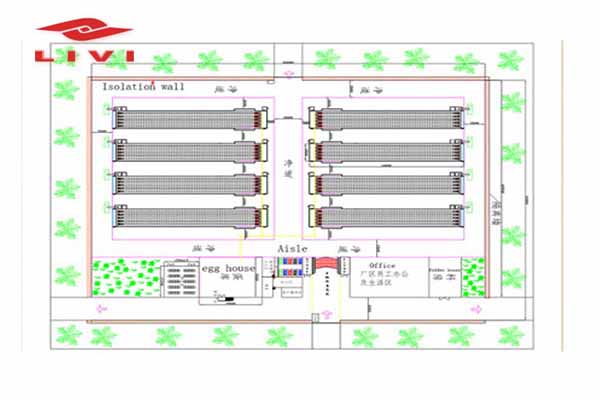

Infrastructure Layout:

The modern poultry farm comprises 8 equally sized poultry houses.

Key facilities include egg storage, staff administrative and living quarters, feed storage, waste management area, disinfection zone, and green spaces.

Each poultry house measures 55*15*4.5 meters, with the entire farm spanning 150*100 meters.

Livestock Distribution:

Dividing the 200,000 layers evenly among the 8 poultry houses results in 25,000 layers per house.

Utilizing H-type layer farming equipment facilitates efficient space utilization and automated management.

H-Type Layer Farming Equipment:

The adoption of H-type layer farming equipment ensures streamlined operations.

Each poultry house necessitates 160 sets of H-type battery cages.

The arrangement involves 4 rows of cages, with 40 sets per row.

Automatic Poultry Farm Equipment Integration:

The Automatic poultry farm equipment encompasses automated waste removal, feeding, egg collection, and environmental control systems.

Automation enhances operational efficiency, reduces labor requirements, and ensures optimal conditions for layer health and egg production.

Optimized Space Utilization:

By employing H-type layer cages and strategic layout planning, the available space within each poultry house is maximized.

Efficient space utilization contributes to higher productivity and facilitates ease of management.

Environmental Considerations:

Adequate green spaces within the farm promote environmental sustainability and contribute to the well-being of the layers.

Proper waste management and disinfection protocols are implemented to maintain hygiene and minimize disease risks.

Staff Facilities:

Provision of dedicated areas for staff administrative work and living quarters ensures a conducive working environment.

Staff welfare is prioritized to facilitate efficient farm operations and ensure employee satisfaction.

In conclusion, the solution presented offers a comprehensive framework for housing 200,000 layers within H type battery cages, integrating automatic poultry farm equipment, efficient layout design, and automated systems to optimize productivity and ensure the well-being of the layers.

If you need to build a modern poultry farm, please leave us a message.